| Type:Secondary Crushing Plant | Input Size:Up to 700mm |

| Processed Materials: Stone with compression strength lower than 350Mpa, such as limestone, gypsum, granite, basalt, andesite, quartz, silica, volcanic rock, marble, river stone, gravel, pebble, pozzolana ,etc. |

Applications: Ore crushing, railway, highway, energy, cement, chemical industry, construction, etc |

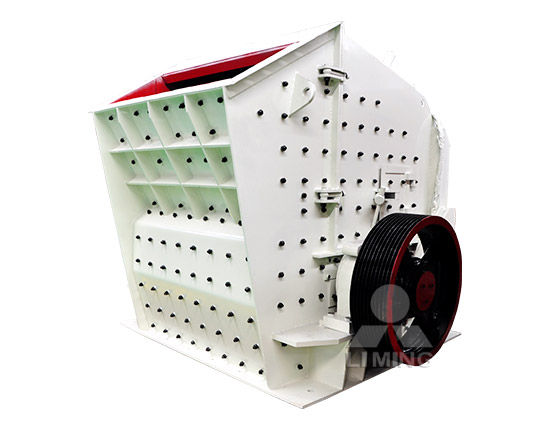

PFW series impact crusher with the advanced world standard is latest generation product, absorbing the latest technology around the world. Because the rotor is the key part of the impact crusher and also the most critical part of inspection and acceptance, our company develop and produce the strong and heavy type rotor in order to get the higher rotary inertia. The use of high abrasion-resistant material and the best design of the crushing chamber make the performance of the crusher more remarkable.

PFW series impact crusher improve the adjusting device, easy to operate. The design of three chamber crushing make the PFW series impact crusher perform well in the fine crushing and superfine crushing operation. The design of the two chamber crushing simplifies the flow chart of coarse crushing operation.

1. Adoption of the world-class manufacturing processes and selection of the most high-end raw materials.

2. Heavy type rotor design and strict testing method to guarantee high quality rotor.

3. Adoption of the Integral cast steel structure on bearing seat makes it matches well with the crushing frame and increases the radial strength of it, while the divided design does not has this advantage.

4. The unique fixing device for hammers,make it more reliable.

5. The hydraulic adjusting device makes the maintenance easier and less.

6. Self-equipped open-top device can quickly complete the replacement of wearing parts such as the hammer.

7. Selection of the bearing with larger size and higher load.

8. Finite element analysis on the rotor to ensure its performance more stable and reliable.

European Type Impact Crusher use impact energy to crush the materials. When materials enter the working area of plate hammer, they are impacted then crushed by plate hammer at a high speed, and are thrown into the impact device installed at the upper part of the rotor for re-crushing, then rebounded into the working area of plate hammer from the impact scale board for re-crushing. This process is repeated until materials are crushed into demanded granularity and are discharged from lower part of the machine.The granularity and the shape of the materials can be changed by adjusting the gap between the impact frame and the rotor shaft.Spring safety device is adopted behind impact plate of the machine. When non-broken materials enter the crushing cavity, the front and rear impact frame fall.

Table 1: for crusher with three crushing chambers

| Model | Rotor size (mm) | Feed opening (mm) | Max. Feed size (mm) | capacity (t/h) | Power (kW) | weight (t) | Overall dimension (mm) |

| PFW1214Ⅲ | Ф1150×1400 | 570×1430 | 250 | 90-170 | 132(175) | 16 | 2550×2310×2100 |

| PFW1315Ⅲ | Ф1300×1500 | 625×1530 | 300 | 180-270 | 200(270) | 20 | 2960×2570×2380 |

| PFW1318Ⅲ | Ф1300×1800 | 625×1830 | 300 | 220-300 | 250(350) | 23 | 2960×2870×2380 |

| PFW1415Ⅲ | Ф1400×1500 | 800×1530 | 350 | 280-350 | 250(350) | 22.5 | 3120x2650x2660 |

Table 2: for crusher with two crushing chambers

| Model | Rotor size (mm) | Feed opening (mm) | Max. Feed size (mm) | capacity (t/h) | Power (kW) | weight (t) | Overall dimension (mm) |

| PFW1214Ⅱ | Ф1150×1400 | 1100x1430 | 500 | 130-200 | 132(175) | 18.5 | 2400x2310x2550 |

| PFW1315Ⅱ | Ф1300×1500 | 1200x1530 | 600 | 180-320 | 200(270) | 21.5 | 2700x2570x2800 |

| PFW1318Ⅱ | Ф1300×1800 | 1200x1830 | 700 | 240-400 | 250(350) | 25.5 | 2700x2870x2800 |

| PFW1415Ⅱ | Ф1400×1500 | 1300x1530 | 700 | 300-480 | 250(350) | 25 | 2900x2700x3000 |

Copyright© 2004-2018 by China Lming Heavy Industry Science and Technology Co. LTD All rights reserved