| Type:Tertiary Crushing Plant | Input Size:Up to 50mm |

| Processed Materials: limestone, granite, basalt, andesite, quartz, silica, gypsum, volcanic rock, marble, river stone, gravel, pebble, pozzolana, Iron ore, copper ore, gold ore, manganese ore, etc. |

Applications: Mechanism sand, bituminous concrete, metal mine, aggregates shaping |

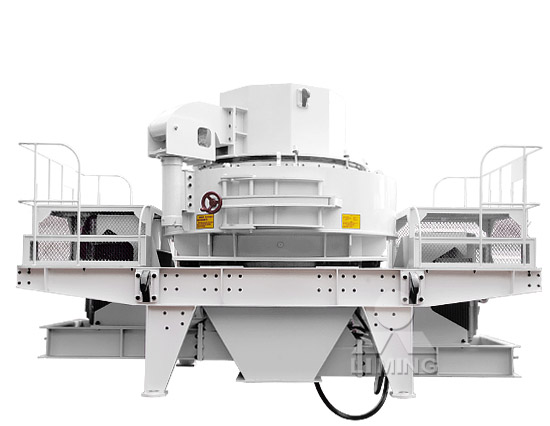

VSI series vertical shaft impact crusher is newly developed equipment, based on our engineers’ many years’ R & D, absorbing the advanced technique overseas, with international advanced stage.

It is of high efficient energy-saving crusher. Its good performance plays a Irreplaceable role in fine crushing of all kinds of ores. This crusher is widely used in crushing and reshaping of metallic and non-metallic ore, building materials, artificial sand and all kinds of metallurgical slags.

1.Advanced double-pump oil lubrication system guarantees the shaft bearing lower temperature increase, longer life time, more reliable operation. It prolongs the maintenance period of the machine.

2.Main shaft is equipped with imported roller bearing. It makes main shaft work stable and then increase the life time.

3.Hydraulic lifting mechanism can move away the feed hopper easily, which saves man power during maintenance.

4.Over-vibration indication and warning device is equipped. There will be alarm when vibration surpasses a stipulated figure.

5.Special dust-proof design for main shaft bearing fully avoids dust entering bearing lubrication part, which will guarantee the machine work normally.

6.Special feed opening structure makes that two feeding methods, center feeding, center feeding & ring feeding, changes easily, in order to meet the requirement of crushing and reshaping stones.

VSI crusher adopts advanced principle of selective crushing and cleavage fracture crushing; impressing enough kinetic energy to materials; impacting strength will convert kinetic energy to crushing energy. Materials will break through the natural lamination and physical edge. It has the features of better shape of final products, but less cost. This machine can realize two working principles’ conversion with "crushing between materials" and "crushing between materials and liners".

| Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | |

| Capacity (t/h) | Center and Ring feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| Center feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Max Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 |

| Hard material | <30 | <35 | <40 | <45 | |

| Rotation speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Power for double motor (kW) | 2×55 (75) | 2×90 (125) | 2×132 (175) | 2×200 (270) | |

| Overall Dimension L×W×H (mm) | 4100×2250×2285 | 4140×2280×2425 | 4560×2450×2780 | 5100×2690×3200 | |

| Weight (t) | 10 | 12.5 | 14.5 | 19 | |

| Lubrication hydraulic pressure station | Power for double oil pump | 2×0.25(0.33) | |||

| Safety | To make sure the supply of the oil with double oil pump; stop working without oil or hydraulic pressure; temperature falls when the water cools; start the motor by heating it in winter. | ||||

| Overall dimension L×W×H(mm) | 820×520×1270 | ||||

| Power for oil box heater | 2 kW | ||||

Copyright© 2004-2018 by China Lming Heavy Industry Science and Technology Co. LTD All rights reserved